AN INTERNATIONAL QUALITY REFERENCE FOR THE PRODUCTION OF GLASS MOULDS AND ACCESSORIES

Materials

Fonderie Valdelsane constantly updates the quality of its products, making them increasingly easier to work with and at the same time more resistant during use.

Our catalogue includes a wide range of special cast iron and bronze alloys, developed and produced to offer our customers the most suitable solution for different needs.

Each of our alloys has been developed with specific objectives of promoting productivity and efficiency in mechanical workshop processes and ensuring the best performance of the moulds during their use.

The K 250 cast irons and bronzes of Fonderie Valdelsane are internationally registered trademarks and cannot be reproduced, for greater protection of glass producers who require high quality standards.

Cast Irons

Our K 250 cast irons represents an international reference point for the production of moulds and components.

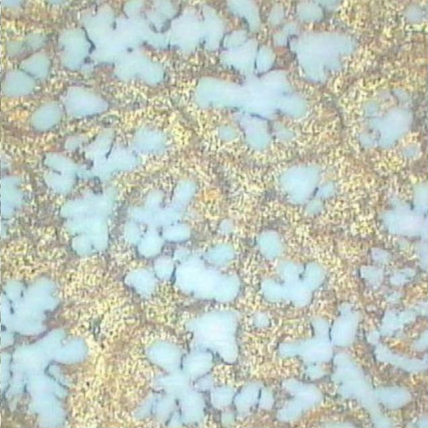

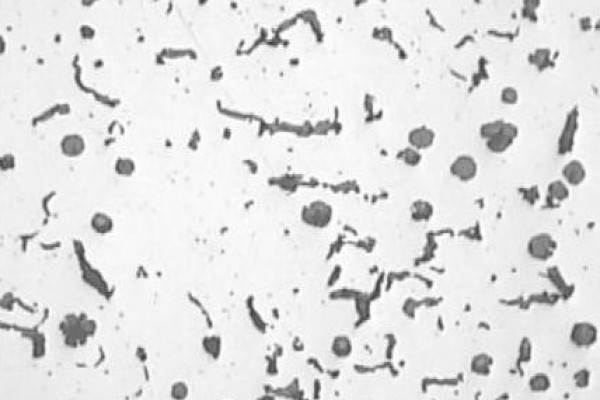

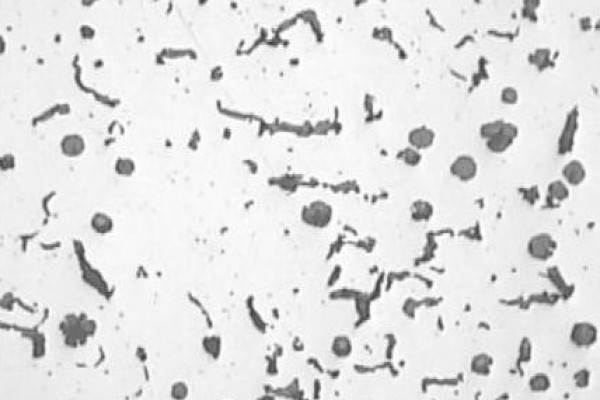

Laminar Graphite

Characterized by a graphitic structure of form I, this type of cast iron allows rapid thermal disposal and it is commonly used for high-speed glass productions.

Laminar graphite alloys are easy to work with, have good mechanical properties, and guarantee excellent welding results. Our catalogue includes various laminar graphite cast irons combining different chemical elements, suitable to the miscellanous needs of the glass industry.

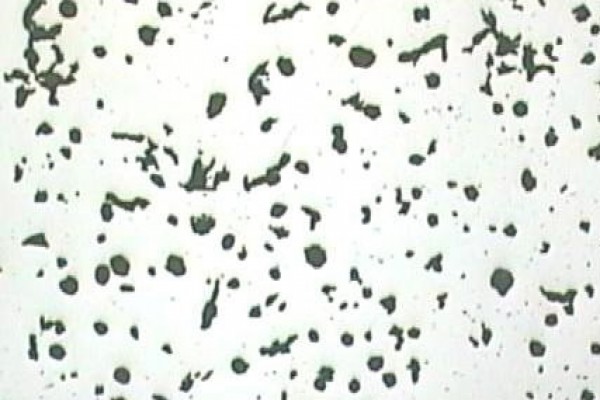

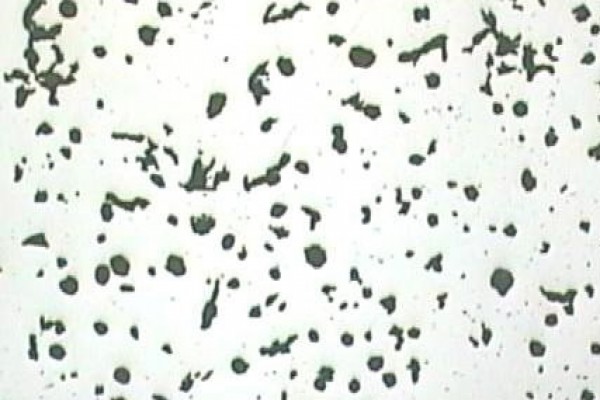

Nodular Graphite

These cast irons are conceived to reach a graphitic structure of form VI that makes the glass contact surface particularly compact and polishable. They are specially recommended for cosmetic and pharmaceutical glass moulds productions, and more generally in the production of high quality glass.

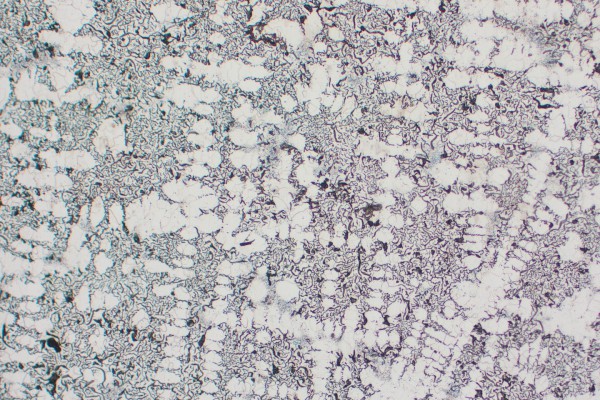

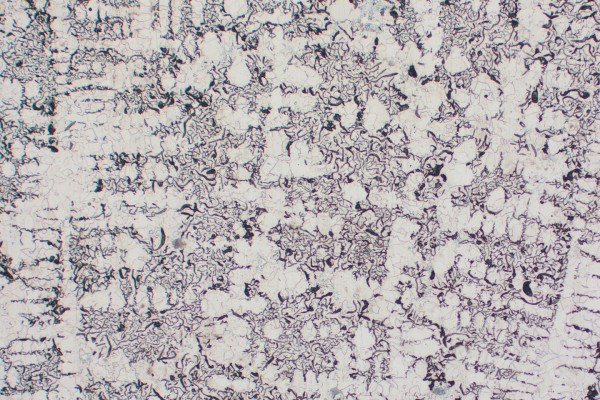

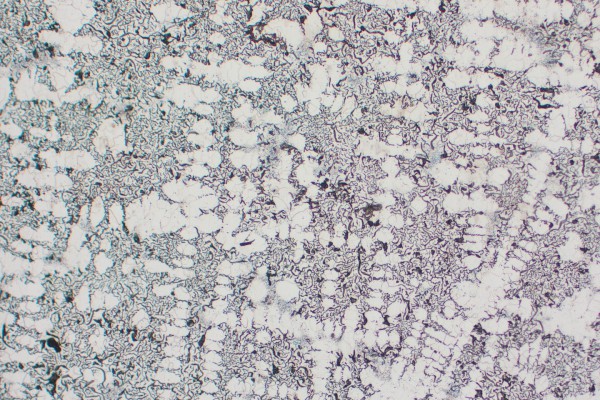

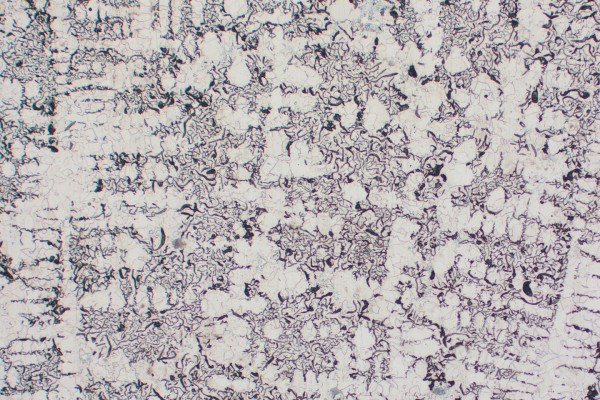

Vermicular Graphite

Known as variable graphite cast iron, it offers excellent resistance to mechanical and thermal stress and at the same time, great compactness in contact with glass.

The Vermicular alloys were developed by Fonderie Valdelsane to meet the special needs of glassworks specialized in the production of premium bottles & spirits. These cast irons have good thermal conductivity and can be perfectly polished.

The excellent properties of these cast irons have allowed their use to be extended to various articles, altough their main use remains linked to the special production of spirits and extra-flint glass.

Cast Irons

Our K 250 cast irons represents an international reference point for the production of moulds and components.

Laminar Graphite

Characterized by a graphitic structure of form I, this type of cast iron allows rapid thermal disposal and it is commonly used for high-speed glass productions.

Laminar graphite alloys are easy to work with, have good mechanical properties, and guarantee excellent welding results. Our catalogue includes various laminar graphite cast irons combining different chemical elements, suitable to the miscellanous needs of the glass industry.

Nodular Graphite

These cast irons are conceived to reach a graphitic structure of form VI that makes the glass contact surface particularly compact and polishable. They are specially recommended for cosmetic and pharmaceutical glass moulds productions, and more generally in the production of high quality glass.

Vermicular Graphite

Known as variable graphite cast iron, it offers excellent resistance to mechanical and thermal stress and at the same time, great compactness in contact with glass.

The Vermicular alloys were developed by Fonderie Valdelsane to meet the special needs of glassworks specialized in the production of premium bottles & spirits. These cast irons have good thermal conductivity and can be perfectly polished.

The excellent properties of these cast irons have allowed their use to be extended to various articles, altough their main use remains linked to the special production of spirits and extra-flint glass.

Bronze alloys

Thermal conductivity, resistance and durability over time

The special bronze alloys produced by the company have been conceived (designed) and developed in order to offer the highest thermal conductivity, ease of metallization and therefore resistance and durability over time.

Since the 2000s, considerable efforts have been made to optimize the technical characteristics and production capacity of this material. Significant investments have been allocated in the research of new chemical compositions and production processes, as well as in the installation of new automated lines dedicated exclusively to bronze casting.

Today, Fonderie Valdelsane is present on the glass market with various high quality bronze alloys.